We transform plastic waste into new products

The Precious Plastic project comes from The Netherlands and was born in 2013 as a degree thesis from Dave Hakkens.

The thesis was based on the design of a machine and a service to contribute to the reduction of plastic consumption. In all these years, the project has developed, the machines have become four, and a community has been created, calling itself with the same name as the project, made up of about 80,000 people from all over the world.

Precious Plastic

An ambitious project whose growth is given precisely by how community members take advantage of it. There are several interesting cases, one of which is that of the social enterprise Koun, in Casablanca, Morocco. A group of young locals takes care of collecting plastic waste, transforming it into objects for the growing middle class: stools, bags, cushions, cups and bowls, lamps and chandeliers, colorful and original. Koun collects its raw materials directly from the businesses, schools or the associations of Casablanca, then uses the waste collected to make its products.

La sede di Precious Plastic a Kisii in Kenya

Each member of the Precious Plastic community shares their ideas and provides useful tools to reduce the consumption of plastic materials. Joining the community is very simple, as it is enough to connect to the website and register. The site can also be consulted without registering, and the portal offers not only the indications aimed at the construction of the machinery, but it also shares the many ideas, information, articles on how to use the material obtained through the machinery. There is also an area called Bazar, which is dedicated to the purchase of a series of objects produced from recycled plastic.

These machines can also be built at home following the instructions that the same designer shared online, in full line with the spirit of the project.

There are currently four invented machines, but they don’t necessarily have to be built all, built because each of them performs different functions even if, by building them all, the complete cycle takes place: from waste to the production of raw materials.

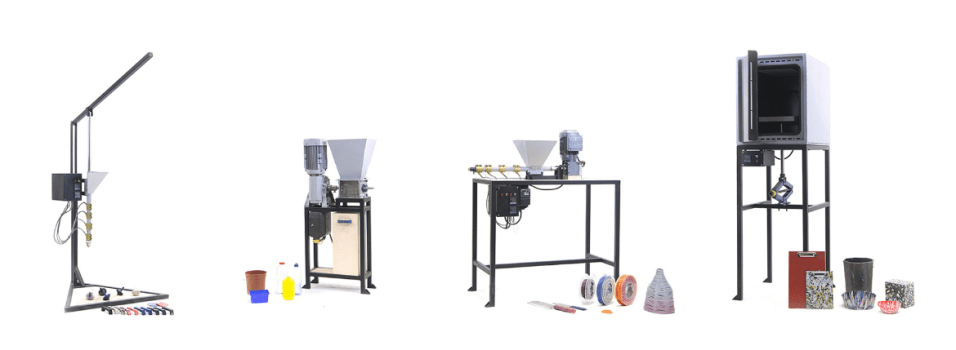

Macchinari di Precious Plastic

- Shredder Machine. This machinery is used to fragment very large plastic pieces into smaller fragments. These small fragments can then be used as components for other machinery or be resold to factories.

- Extrusion Machine. Extrusion is a continuous process during which plastic fragments are inserted into the hopper and extruded into a plastic line. The extrusion machine works continuously, therefore, in theory, if you have enough plastic available and a well structured process, it would be possible to recycle 24 hours a day, 7 days a week. With the extrusion machine you can create filamentary residues, granular or work creatively with the mold.

- Injection Machine. This more advanced type of machinery allows you to create very specific objects in a relatively short time. The initial difficulty is to create the mold correctly, but once made, this machine can create many objects. Usually the objects that can be made are small, and the final color is difficult to predict.

- Compressione Machine. This machinery is used to make large objects, but works slower than the first three. Thus, finished products or new raw materials can be obtained.