Light-footed Material Innovation: How to Reduce the Environmental Impact of Footwear

It is estimated that the footwear industry, with its mass production accompanied by a progressive reduction in the lifespan of products, is responsible for 1.4% of global GHG emissions, corresponding to 700 million tons of CO2eq. Of these, 34% is attributable to materials (source: Assomac), not only the more traditional but highly impactful ones such as leather, but also those based on petrochemicals, used in particular for sneakers and sports shoes, types in strong growth.

However, in an era in which sustainability is becoming a global priority, this sector is also responding with innovation and creativity. From recycled fabrics, to leather alternatives, to plant-based materials, footwear is undergoing a radical transformation that aims to reduce the environmental impact, while maintaining high standards of quality and design.

The strategies adopted by brands can vary, with many opting for alternative materials to leather—often incorporating a “cruelty-free” approach. These materials are partially bio-based or recycled, and are used not only in the upper part of the product but also in the sole. They frequently originate from agricultural or industrial waste, resulting in a reduced environmental impact due to the recycled components or the carbon content derived from renewable sources. Additionally, some of these materials are produced through fermentation processes that require minimal energy and generate very low emissions.

Others focus on biodegradability: the US company Blueview, for example, uses plant-based materials tested to degrade in the presence of oxygen (according to ASTM D5338 standard) in 200 days. The sole is made of biobased polyurethane foam, while the upper is made of a textile material alternative to leather obtained from hemp and eucalyptus yarn.

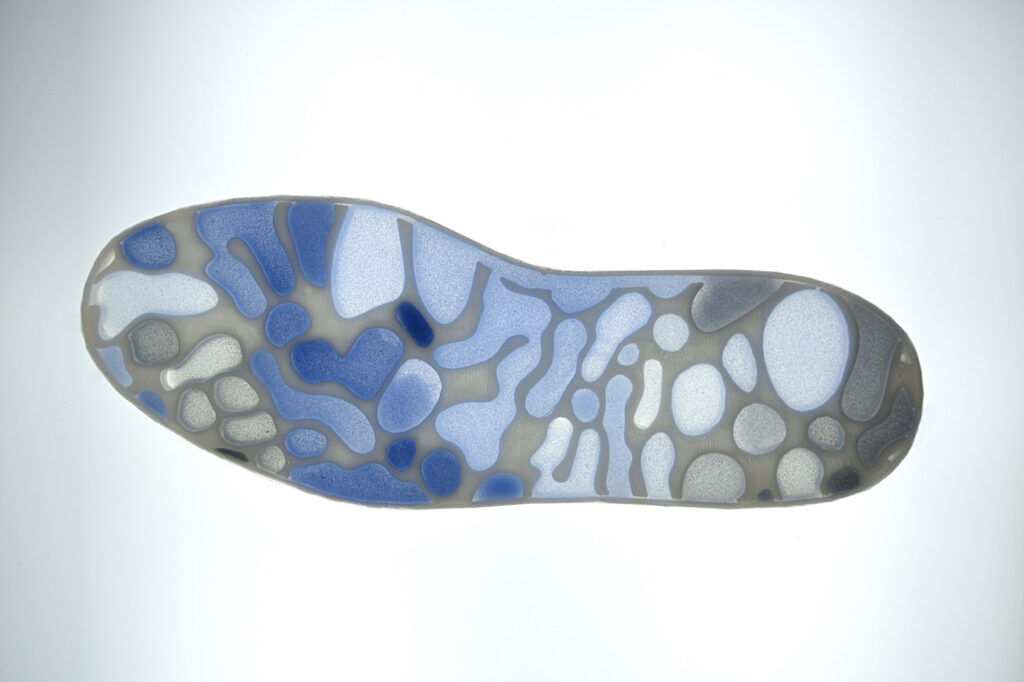

Puma has been focused on improving the biodegradability of materials for many years. As early as 2018, the brand introduced an experimental project in collaboration with MIT, showcased by Material ConneXion Italia (now Materially) during Milan Design Week. The project, known as the Breathing Shoe, featured a “biologically active” design with a sole that was intentionally “biodegraded” in specific areas to create a perforated pattern. In 2021, Puma successfully tested the RE:SUEDE concept, which incorporates Zeology-tanned suede—a natural tanning process using zeolites—and a TPE and hemp fiber sole. This concept was tested for industrial composting, with the goal of developing a process capable of treating items that decompose more slowly than standard organic waste.

This is now complemented by the RE:FIBRE polyester recycling program, developed by PUMA’s “Circular Lab”, an innovation hub led by PUMA’s innovation and design team with the aim of creating tangible circularity strategies for the company.

To meet these new demands from the footwear industry, Materially is working on a service, developed within the European project SoTecIn Factory, for the integration of data on the sustainability of materials in footwear design software, with the aim of introducing sustainability criteria starting from the design phase with a view to measurability and transparency of the production chain. SoTecIn Factory is a project funded within the Horizon Europe program and in turn supports innovation initiatives with a high social and environmental impact.