SoTecIn Factory – Generate, Transfer, Measure Impactful Changes

For Materially, 2024 began under the keyword impact. In January, we passed the selection of the EU project SoTecIn Factory to enter a community of twenty-five innovative companies and startups aimed at generating a change in European value chains towards sustainability and circularity. We therefore had the opportunity to address various aspects of the concept of impact, from the strictly environmental one to broader social and governance implications.

Materially has thus entered a wide-ranging ecosystem of social innovators, starting with the partners of SoTecIn Factory, including entities such as the global network Impact Hub, the system-thinking experts Metabolic and the Italian CNR – National Research Council. Among the large group of companies that participated in the various phases of the project, many are startups with a focus on innovative materials and processes. Among these are Raiku, an Estonian manufacturer of packaging utilizing wood waste; Noosa, a Belgian company that produces totally recycled and recyclable yarns thanks to a patented process; Papair, a young German group that offers an alternative to bubble wrap in which polyethylene is replaced with paper.

Participating in SoTecIn Factory enhanced our understanding of and ability to implement a business approach aimed at social impact and its measurement, aspects that are increasingly relevant in the context of Agenda 2030 and ESG assessments. Particularly interesting were the holistic approach of the training, and the implementation of system change principles rooted in the Club of Rome, the inspiration of one of the most profound and effective methods of contextualizing ecosystem problems developed in the last fifty years.

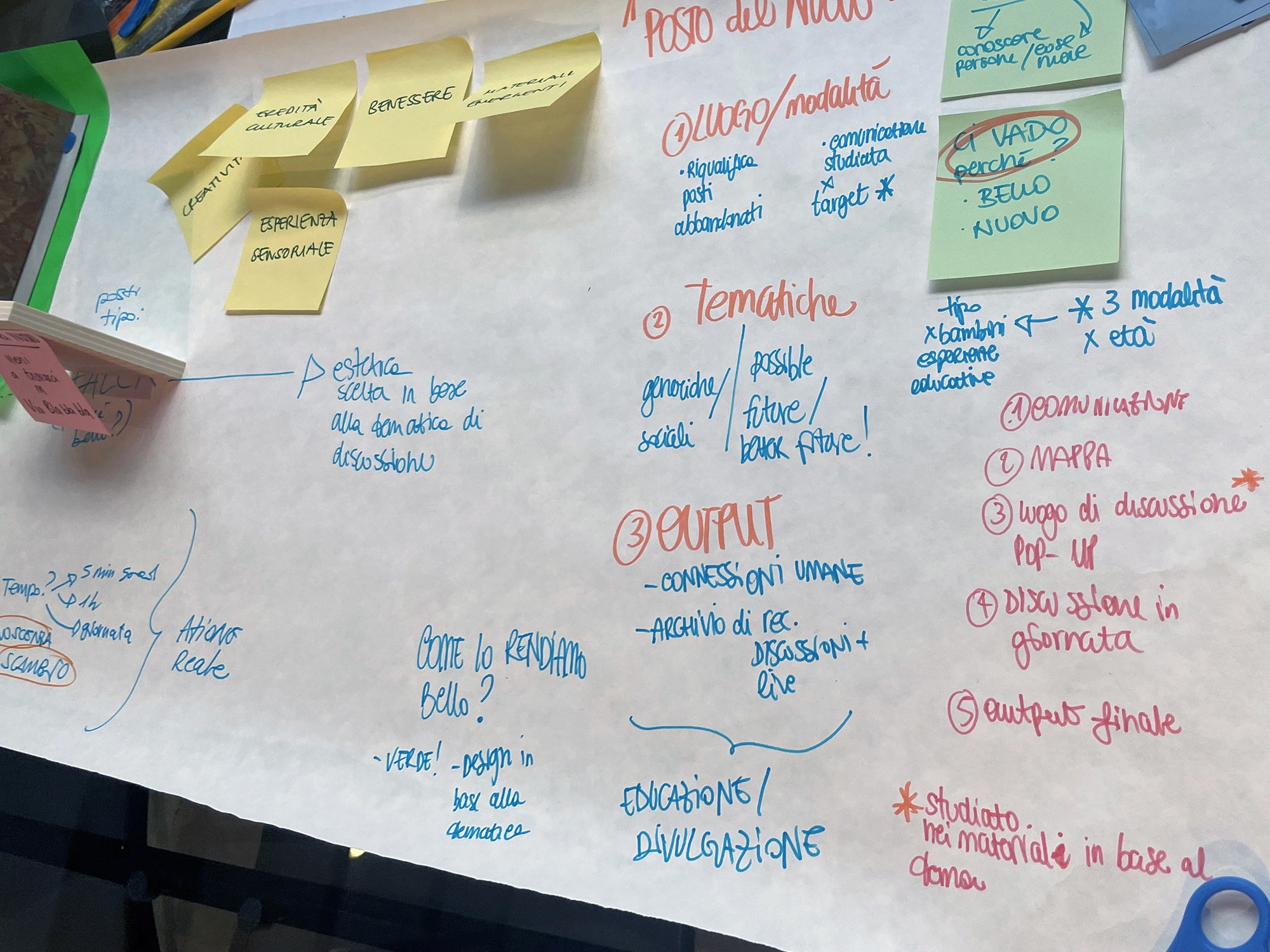

The intensive capacity building phase ended at the end of June and thanks to its transversality it allowed us to put into a new perspective aspects of business modeling, IP strategy, governance solutions, environmental and social impact assessment, financing opportunities and many others. This knowledge was channeled into the in-depth design of the solution we had proposed for the initial selection: a digital tool facilitating the circular transformation of footwear production starting from materials.

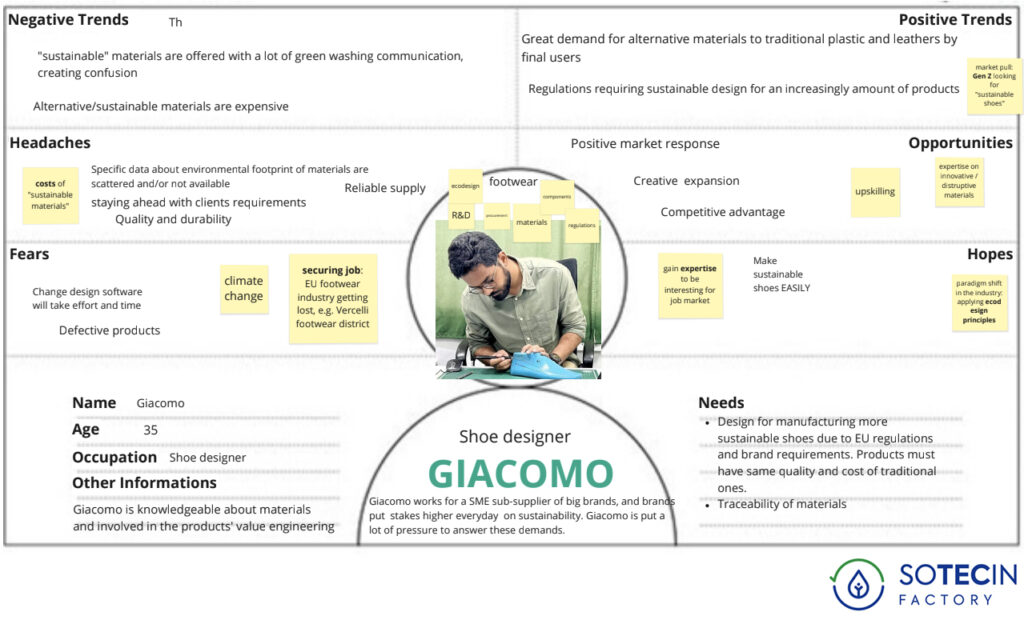

The solution, CIFORCE-F (Circular Footwear Resource Finder), originally responded to a challenge proposed by the Politecnico Calzaturiero highlighting the lack of tools supporting the search and application of sustainable materials and circular solutions in the footwear sector. In the second phase of the project, we will have the opportunity to deepen and validate a technical solution focusing on materials as means to reduce the footwear industry environmental impact.