Exploring Traditional and Innovative Sustainable Materials in the Furniture Industry

H.H.H. Chairs, Kartell

The entire Italian manufacturing industry has been exploring ways to reduce emissions for a long time, and the wood-furniture sector is no exception. Individually and collectively, it has embarked on a journey to redefine its production methods and product management, starting with the selection of materials.

This direction of development is vividly reflected in the theme chosen for FuoriSalone 2024 – “Materia Natura,” emphasizing the intrinsic connection of the furniture sector with wood and its derivatives. This sector is deeply intertwined with agro-forestry and sustainable tree management, which significantly contributes to CO2 absorption, emphasizing the importance of responsible resource usage.

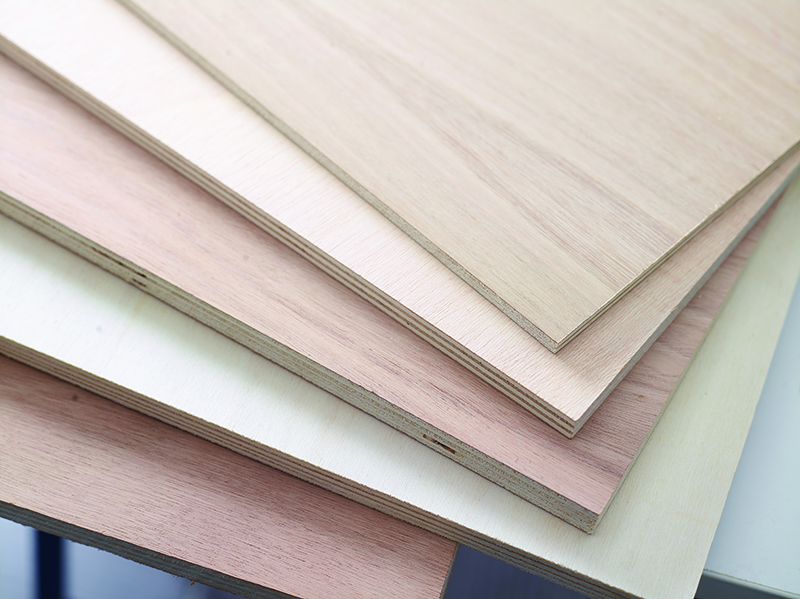

Respect for this invaluable resource has led to the adoption of various solutions, which complement each other. These range from certified timber, predominantly used in high-end furnishings due to its high durability, to wood derivatives sourced from local supply chains. The latter utilizes every part of the trunk, producing first plywood, and then chipboard from leftovers. Additionally, there’s a growing trend towards post-consumer recycled panels (including chipboard and MDF), an area where the Italian industry excels, boasting an efficient supply chain and advanced machinery capable of transforming wood waste into new materials.

Another prominent material in the sector is kraft paper, widely used in laminates and panels, often combined with binders (typically resins) to enhance strength and durability. The binder sector is witnessing advancements aimed at reducing emissions not only during production but also throughout the product’s lifecycle. An exemplary product in this realm is Catifa Carta, a redesigned version of the classic Catifa 53 chair, launched in 2001 by Arper. Catifa Carta is made of PaperShell, a composite material made of kraft paper and a bio-based binder, layered and pressed together. PaperShell sequesters more carbon dioxide than is released during the manufacturing process (the carbon sequestration potential of 1kg of PaperShell is approximately 1.5kg CO2 equivalent) acting as a “carbon sink” material.

In the realm of plastics, Kartell stands out for its offerings with recycled content, both mechanical and chemical. Notable examples include the console from the My A.I. Evolution line, designed by Philippe Starck, and collaborations with Illy for the recycling of coffee capsules, yielding innovative new products.

Furthermore, in projects like H.H.H. Her Highest Highness (also by Philippe Starck, with new liberty-style decorations printed with “Graphic Impression” technology, very impactful especially in the super-glossy version), a blend of recycled polycarbonate and bioattributed tallol, a processing residue from kraft paper production, showcases the industry’s commitment to sustainability.

Beyond materials, systemic initiatives are shaping the industry’s future. FederlegnoArredo has developed a digital sustainability platform for its members, featuring a library of sustainable materials designed in collaboration with Materially. This initiative aims to assist companies in material selection, accelerating their knowledge and implementation to enhance the environmental profile of products. Additionally, the sector is actively engaged in establishing end-of-life management supply chains, aligning with the objectives of Extended Producer Responsibility and the broader goal of achieving Carbon Neutrality in the coming years.

By embracing both traditional craftsmanship and innovative technologies, the Italian furniture industry is paving the way for a sustainable and environmentally conscious future.

Do you produce a material with sustainability characteristics for the furniture sector? Contact us to become part of the FLA-Plus platform!