Smart Textiles: advanced fabrics for improved functionality

Smart textiles are textiles that showcase an active behaviour based on external stimuli.

These advanced fabrics possess the ability to sense, actuate, and respond to the environment or user inputs, creating interactive and intelligent experiences.

Their responsive behaviour can be activated by electronic systems (e-textiles) or by other, non-digital technologies such as thermal, chemical or magnetic signals.

By integrating electronic components, sensors, actuators, data processing, storage and other sensing capable technologies within their structure, smart textiles can be seen as wearable computers that can monitor and enhance the wearer’s experience in unprecedented ways. We report here some interesting cases merging cool functionalities with design.

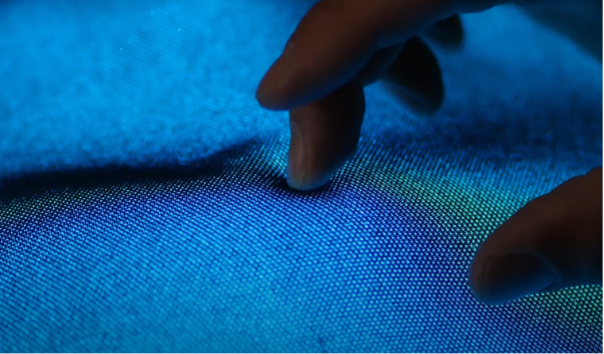

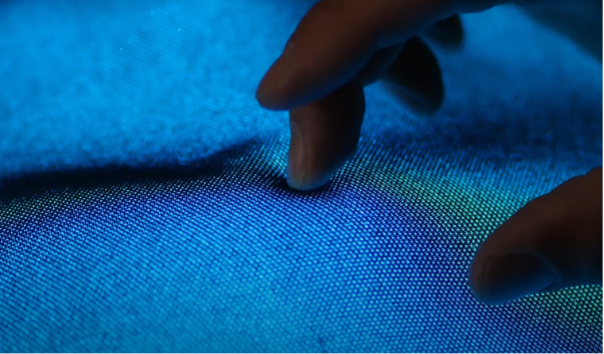

Light integration

Light can usually be integrated into textiles by merging a LED light source and a textile material in such a way that single fibers or a single fabric act as a “guide” of the light source. Transparent PMMA plastic optical fibers are intertwined with white polyester fibers to form mats of fibers that guide the light. The individual fibers are then joined into a ferrule, which in turn is connected to the LED modules.

Munda Textile System image source here

Munda Textile System image source here

In other cases, LED diodes can be directly embedded within the textile, thanks to the integration of conductive yarns that are intricately embroidered with other yarns

The textiles are then produced using commercial machinery that have large production runs, including numerically controlled sewing and weaving techniques. As this is a specialized material, the textiles are usually made-to-order.

E-broidery technology for LED integration in textiles

E-broidery technology for LED integration in textiles

In order to generate light, both these systems require an energy source that is simply provided by the grid or by the implementation of a battery pack.

Conductive systems

New technologies for the integration of resistive heating systems allows the creation of heat-generating clothes. Thin, screen-printed, stretchable, and washable heaters can nowadays conform to various surfaces for wearable applications. These fixed resistance heating elements are made of layers of conductive silver and carbon inks sandwiched between 2 layers of TPU (thermoplastic polyurethane), then laminated onto the textile.The design specifications and ink used dictate the heating properties. These circuits provide supplemental heat for next-to-skin applications while maintaining comfort, withstanding up to 50 washing cycles.

Applications include wearables, compression clothing, joint braces, medical devices, therapeutics, as well, as industrial and automotive parts.

Energy harvesting

A couple of years ago, researchers at Finland’s Aalto University developed a piece of clothing with concealed solar panels, making the technology invisible to the naked eye. The goal of the Sun-Powered Textiles project was to create an energy-autonomous product capable of powering wearable devices – such as sensors that measure humidity or temperature – without disrupting the look of a garment. Traditionally, integrating photovoltaics in textiles was simply made by attaching solar cells on the front surface of a textile, which significantly compromises the aesthetics. Instead, the multidisciplinary team hid the solar cell underneath the textile of this prototype jacket and optimized the fabric so that enough light could pass through to power the wearable.

The Sun-Powered Textiles project was made by Aalto University physics and design students

The Sun-Powered Textiles project was made by Aalto University physics and design students

Could you imagine yoursel wirelessly recharging your phone by simply putting it in the pocket and enjoying a walk in the sun?

Sensing Textiles

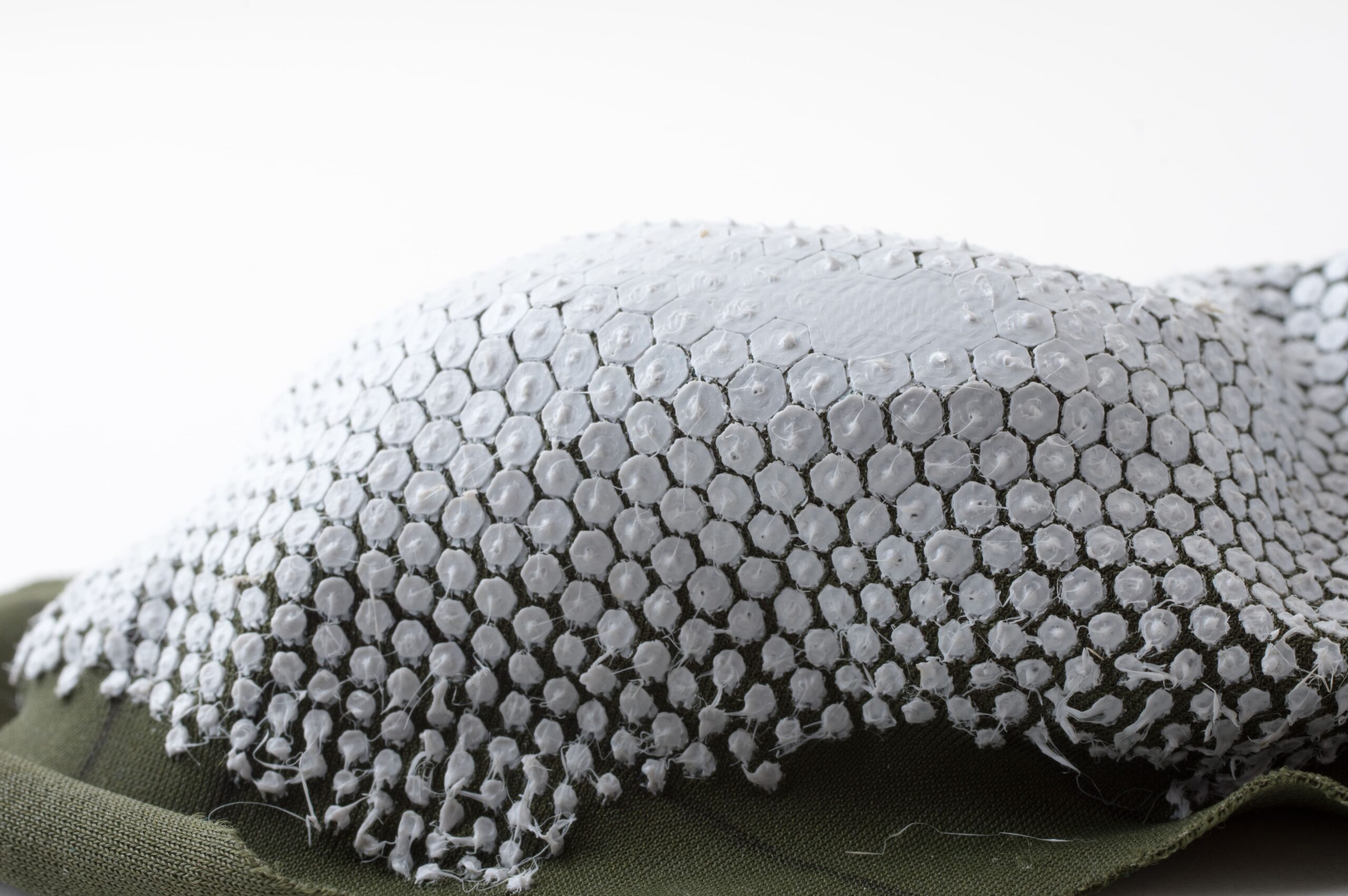

Caress of the Gaze di Behnaz Farahi

Caress of the Gaze di Behnaz Farahi

Caress of the Gaze by Behnaz Farahi is an innovative, nature-inspired wearable created using 3D printing technology. It was designed to interact with its surroundings by detecting the gaze of other individuals and responding with lifelike behavior. The smart textile is made by a combination of a camera sensor, shape-memory materials and shape-memory alloy actuators (SMA) that are utilized to inform the motion of the printed skin, enabling dynamic movements and responses.

This interactive wearable captures the attention of others and engages with them through its realistic and responsive actions. The project showcases the potential of the latest 3D printing technologies and, by exploring the tectonic properties of the materials used, including their flexibilities and densities, the project demonstrates how these technologies can contribute to the fashion industry.

Taking into account the various cases and potential applications, smart textiles are an emerging field that combines technology and fashion to create innovative solutions for various needs and challenges. They have the potential to transform the way we dress, communicate and interact with our surroundings: smart textiles are not only functional but also expressive, creative and fun.