Materially @ Cersaie 2022: new proposals from the ceramic and glass industry

We visited Cersaie in Bologna, the international ceramics fair that hosted over 600 exhibitors to promote their novelties and innovations to an audience of over 90,000 visitors from all over the world.

Here the presence of the major players in the market, together with that of small local artisan businesses, connect the incredible quality of the techniques typical of the artisan tradition to the most advanced technologies available in the field of ceramic materials.

What are the development directions of greatest interest in the sector? We have selected three significant examples from the most recent aesthetic, technological and sustainability developments.

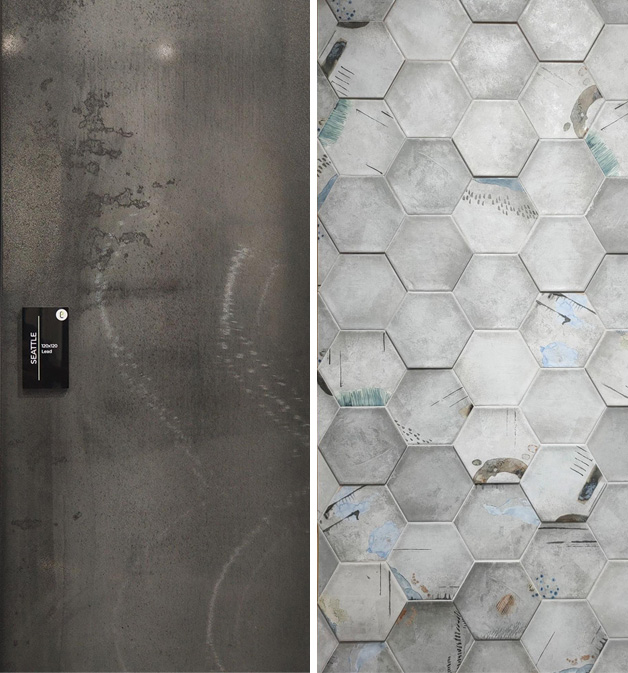

Hybrid aesthetic effects: ceramic becomes metallic

As already emerged from the last editions, ceramic surfaces tend to hybridise with metals through surface treatments that give a metallic appearance to the slabs, with both visual and performance effects.

Maintaining the typical advantages of a ceramic material such as warmth to the touch and a soft and smooth texture, the technology used is based on the application of a 3-layer coating followed by controlled abrasion, which allows incident light to be reflected back to the the same way it would be on a metal surface, with stunning and impressive visual results.

Ecoceramic: 3D glow effect for metal like effect / Akcoat: installation promoting recovering processes for inkjet inks in the ceramic industry

Reduction of the environmental impact throughout the life cycle

Compared to other materials used in architecture, ceramic stands out for its durability, which often exceeds 50 years of life. But being essentially made up of three fundamental elements such as water, earth and fire, the manufacture of ceramic materials inevitably translates into a production with a high impact in terms of resources and energy.

With the aim of improving the overall sustainability of these systems, companies in the sector focus on different strategies: from the development of ultra-thin ceramic slabs, which reduces the use of raw materials by up to 65%, to the use of renewable energy, up to offsetting emissions to achieve carbon neutral production.

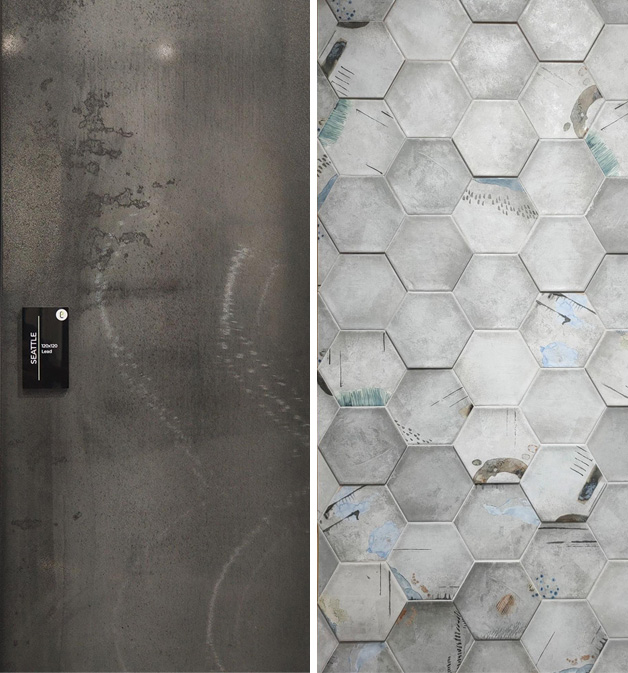

On the recycling front, in addition to the use of recycled raw materials (in particular the glass component), dry laying systems are developed, where the use of adhesives is not required, allowing the coatings to be reused for new projects and in case of renovations.

Traditional ceramics from Sardinia / Artistic installation from La Faenza group

Circular color

A very important aspect in choosing a ceramic coating is certainly color. More and more sophisticated printing technologies allow to obtain effects of incredible verisimilitude and visual quality. And yet the coloring techniques involved in the decoration processes generate an impact in terms of the product’s environmental footprint.

Life Replay is a European project, in which various players in the sector participate, aimed at creating a new circular value chain for inkjet inks used in the sectors of ceramics, decorative glass and cathode / anodic applications. The project aims to develop processes for the use of ink waste as a raw material for the manufacture of ceramic pigments, inks and tiles.

SICIS Omnigem vetrite panels

LifeReplay | A new concept to reuse waste from the ceramic industry.