Chameleonic products: this is how they are obtained

What allows a product to change color under our eyes and our hands?

Contrary to what it might seem, these are not special plastics, but special “chameleonic” additives (masterbatches) that are added to the polymer that you intend to use.

The “special effects” that can be obtained are manifold and, depending on the type of masterbatch used, the color change of the material can take place in response to heat, during exposure to sunlight or when the product is wet from water.

These special additives can be found in the form of liquids, powders or granules and are formulated to be compatible with various plastics.

The masterbatches, added during the transformation phase of the plastic material, blend with the matrix of the base polymer to create the final product with the particular chameleon effects.

An example is the Thermobatch additive which allows to include thermochromic microcapsules in a polymer matrix resulting in a product that changes color in reaction to certain temperatures.

Once the temperature programmed to start the “mutation” is reached, the microcapsules from their original color become colorless and transparent, thus revealing the color of the plastic matrix to which they were initially added. Therefore, what at first glance looks like a color change is nothing more than the revelation of the base color that remains hidden until the masterbatch becomes transparent.

This transformation is completely reversible: when the material cools back to the initial color.

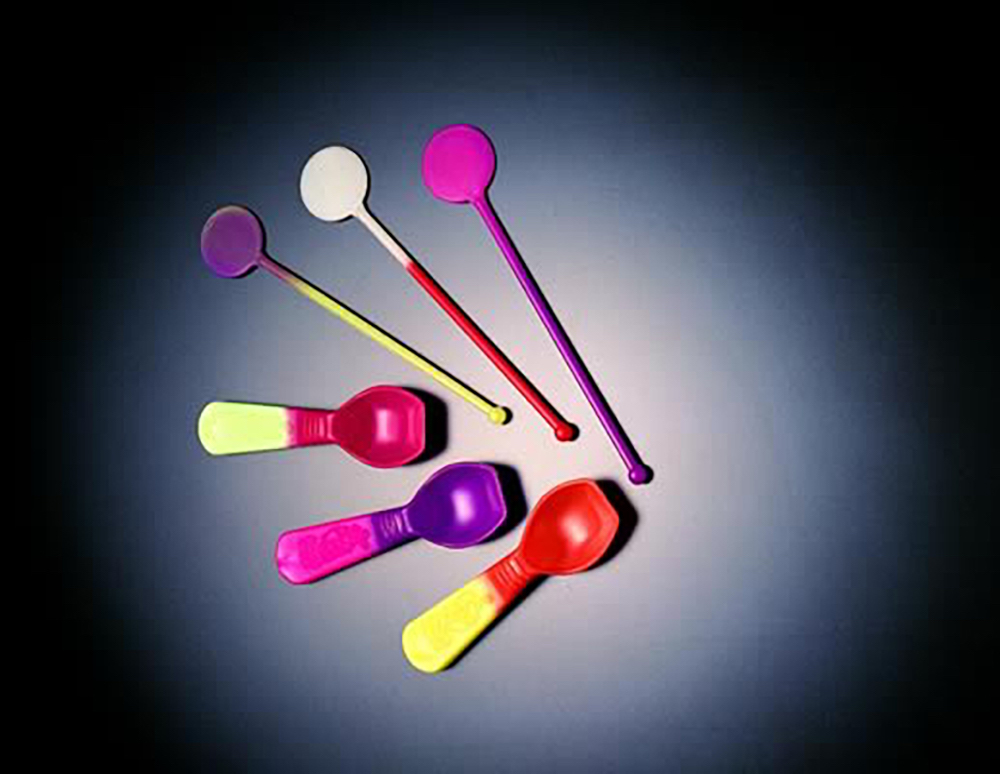

The standard color range is wide (blue, black, green brown, fuchsia, orange, purple, red, turquoise, yellow) and it is also possible to obtain customized colors by combining the masterbatches together.

The “special effects” are truly manifold: from colored to white or transparent, from one color to another, from a soft shade to a stronger shade of the same color. The color change can be programmed in response to cold, warm and hot temperatures, with intervals between -10 ° C and 69 ° Celsius.

The possible applications are also many and different: from the disposable thermometer to plastic products such as cutlery and straws up to the most varied gadgets.

Finally, the use of these additives is not limited to the plastics sector: in fact, thermochromic inks exist for printing and coloring textile products and paper supports and thermochromic paints applicable by spray on glass and wood surfaces.