Three materials to heal the future

Self-healing materials present nowadays a new perspective as an emerging class of smart materials designed to increase durability, reducing maintenance and extending the functional lifespan of products, due to their self repairing capability after a damage occurs.

Thanks to their versatility and safety, this class of materials often finds application in fields ranging from design and soft robotics, to engineering and biomedicine, opening possible visions for the future of design.

From the Material ConneXion database we have selected three examples that show how different classes of materials —such as liquids, gels, or elastomers — can be processed for different applications.

This elastomeric material is capable of healing from scratches and deep cuts thanks to its matrix structure. The material is completely safe and atoxic, as it’s entirely made of acrylate resin corn-derived.

The self-healing properties are given by the intrinsic capability of the material to create new bonds after a damage occurs.This means that if the material is cut and stuck back together, it recovers spontaneously. Bonding between molecules happens due to van der Waals forces that act as an adhesive between them, allowing the material to repair itself within 24 hours.

The elastomer can be molded into various shapes by casting it on a mold before the polymerization process. This allows the customization of the material through dyes and pigments that can be added prior. The material can be purchased as a liquid base or as a molded product (sheets, molded shapes, etc.), allowing a range of different industries to take advantage of its structure. Applications for this material range from soft robotics (actuator) to adhesives, and its inert properties make it suitable for medical simulators (organ models) and kids’ toys manufacturing.

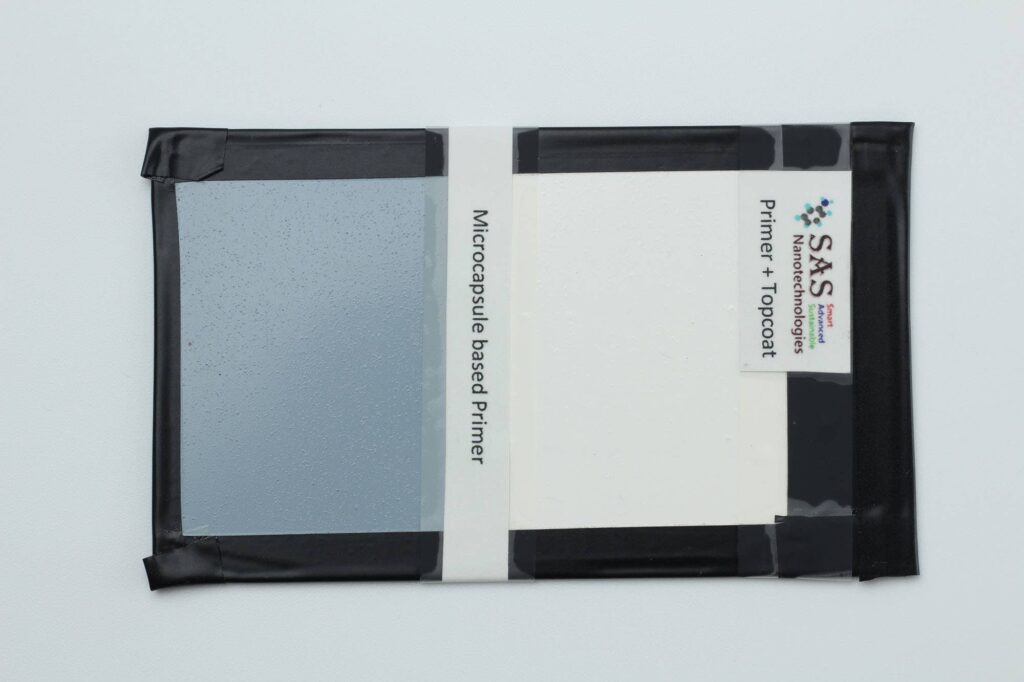

This smart, self-healing and anti-corrosion coating, can self heal under extreme conditions. The company has developed a non-toxic polymer based coating with embedded microcapsules that release their encapsulants when external triggers like scratches or electrochemical potential, voltage, reduction, etc. occur. This approach gives the ability to control the release of encapsulants at-will, opening up opportunities to solve a variety of challenges.

Traditional anti-corrosion coatings contain toxic metal ions such as chromates, zinc, and lead. As corrosion spreads, it causes the coatings to flake and peel, damaging not only the environment but also human health. To solve the problem, this material uses eco-friendly, water-based inhibitors that prevent flaking and reduce maintenance.

As the goal of the company is a world with corrosion-free structures made with environmentally sustainable coatings, this material has already reached numerous industries, making it suitable for construction, marine, automotive, aerospace, and architecture.

This hydrogel elastomer is capable of healing, reforming its polymer matrix even after it’s been deep cut. It takes 24 hours to completely heal, thanks to its elastic structure made of 37% acrylic resin, 37% glycerine, and 26% water.

Along with its self-healing and water retaining capabilities, the material is highly elastic (6~10x) with shape memory properties, strong resistance to high pressure, and high toughness. It can maintain 60-70% strength of his total, after multiple cuts and damages.

It comes as a liquid kit that the user can mix and pour into molds, making it customizable with materials, dyes, and pigments before solidifying. The material is safe, non-toxic, and non-irritating, making it suitable for medical prototyping and toy manufacturing, extending product life and lowering maintenance.

Contact Materially to learn more about the Materials Insights subscription from Material ConneXion: thousands of contents and trend reports on innovative materials, plus access to the Materials Library, featuring a database of 10,000 cutting-edge materials you can explore for your innovation projects.

For more information, please write to info@materially.eu.