Circular Fashion: how innovative manufacturing can reduce the environmental impact of the Fashion & Accessories sector

The fashion design and accessories industry is one of the most impactful in the world from an environmental perspective, both due to the high consumption of resources (water, energy, raw materials) and mass production, with resulting massive amounts of waste. In recent years, the narrative on sustainability in the fashion system has focused a lot on materials: recycled fabrics, vegan alternatives to leather, or bio-based materials. However, to truly address the climate challenge, it is essential to look beyond the simple choice of materials.

Fashion Design: circular fashion beyond materials

Today, new production and management approaches offer concrete solutions to reduce the environmental impact of the sector. Circular economy, energy optimization, waste reduction, supply chain transparency, and digitalization are paving the way for a more sustainable and responsible fashion industry.

On-demand production and additive manufacturing

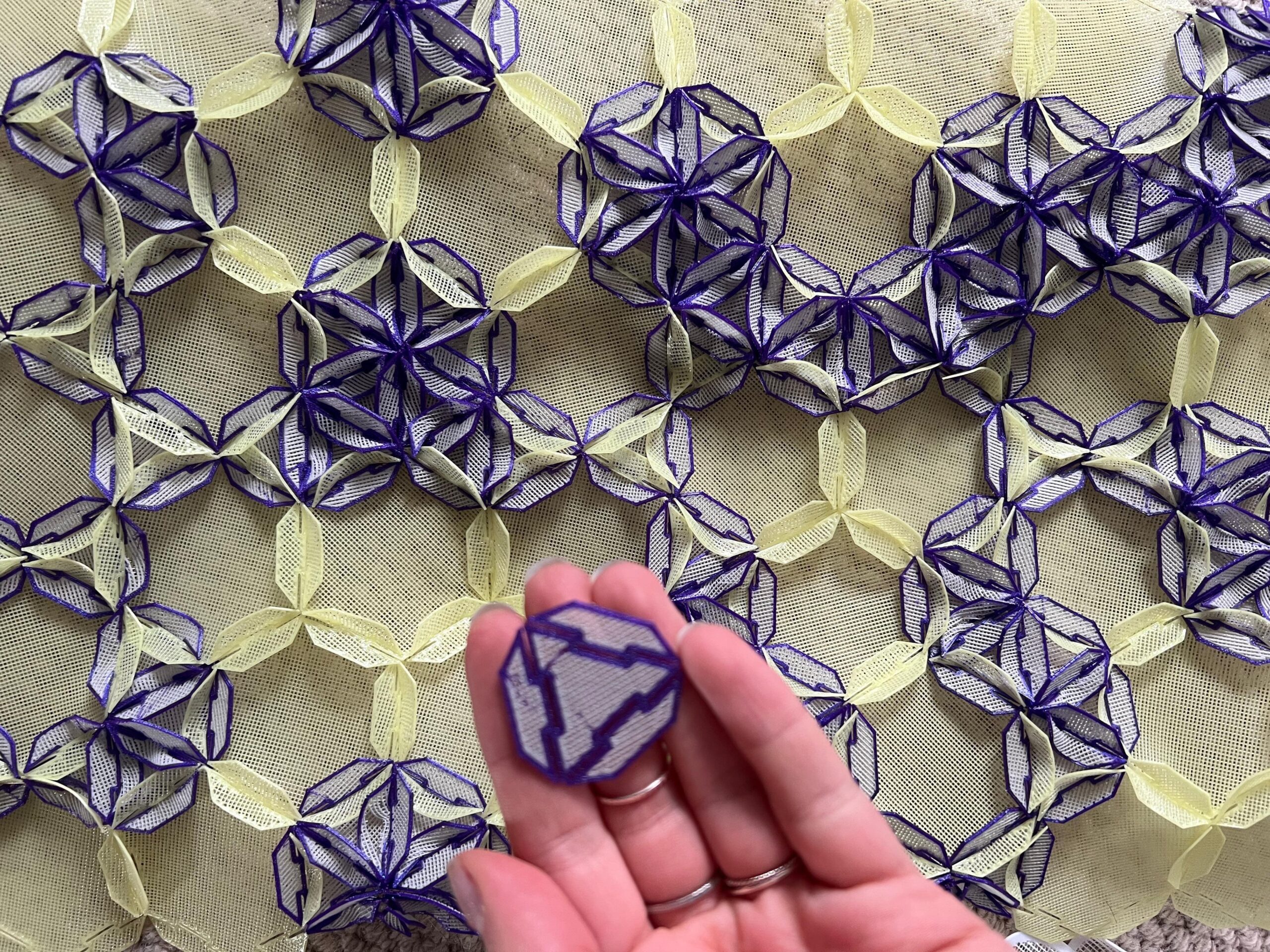

Among emerging models, the on-demand approach allows for producing only what is actually requested, reducing excesses. In Northern Europe, micro-labs of 3D knitting offer digital platforms to create customized pieces on the spot, as in the Adidas “Knit for You” project launched in 2017 or, more recently, as proposed by the Dutch start-up New Industrial Order.

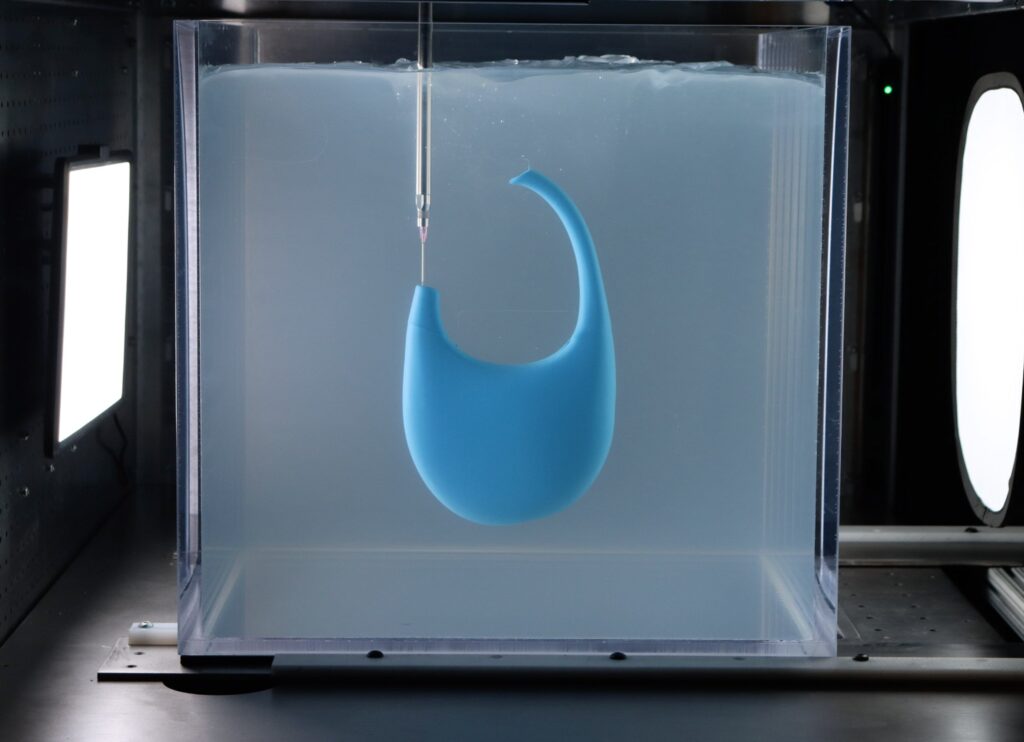

Today, even large brands are experimenting with this model to reduce the waste of mass production. Meanwhile, additive manufacturing, such as 3D printing, allows for more efficient production, as building the product layer by layer significantly reduces waste. An iconic example is the Ariel Swipe Bag by Coperni, printed in liquid silicone.

Design for recyclability in fashion design and accessories

Design for recyclability is another innovative front. The startup Resortecs has developed a thermosoluble yarn that facilitates the disassembly of garments, improving the efficiency of recycling. In addition to launching several pilot projects with many brands, the company is collaborating with Sioen to create a circular supply chain in workwear.

Beyond fashion, the accessories sector – particularly footwear – is exploring circular design through the use of monomaterials or easily disassembled modular structures. Adidas, with the Futurecraft Loop project launched in 2019, created a shoe entirely made from thermoplastic polyurethane, fully recyclable. More recently, the Climacool has further developed this concept. The brand On, with its shoe Cyclon, has focused on polyamide and a product return system to promote circularity. It is therefore not just about using recycled materials, but about designing for recyclability, ensuring that the product can actually be reintegrated into the production cycle at the end of its life.

Towards a sustainable fashion system

Sustainable fashion, therefore, requires a deep change that involves materials, processes and even mindsets. The new production models – on-demand, circular, and digital – represent a real answer to the environmental crisis within the sector.

Cover image credits: 3D printed modular flexible material by Variable Seams.