Recycled and recyclable plastics: what are we talking about?

As attention to the environmental problems generated by the over-consumption of plastic materials grows, the industry proposes more sustainable solutions, often recycled and/or recyclable.

But what exactly do these words mean? What should we expect in front of a product that defines itself as “recycled”?

Here is a quick glossary of some basic concepts.

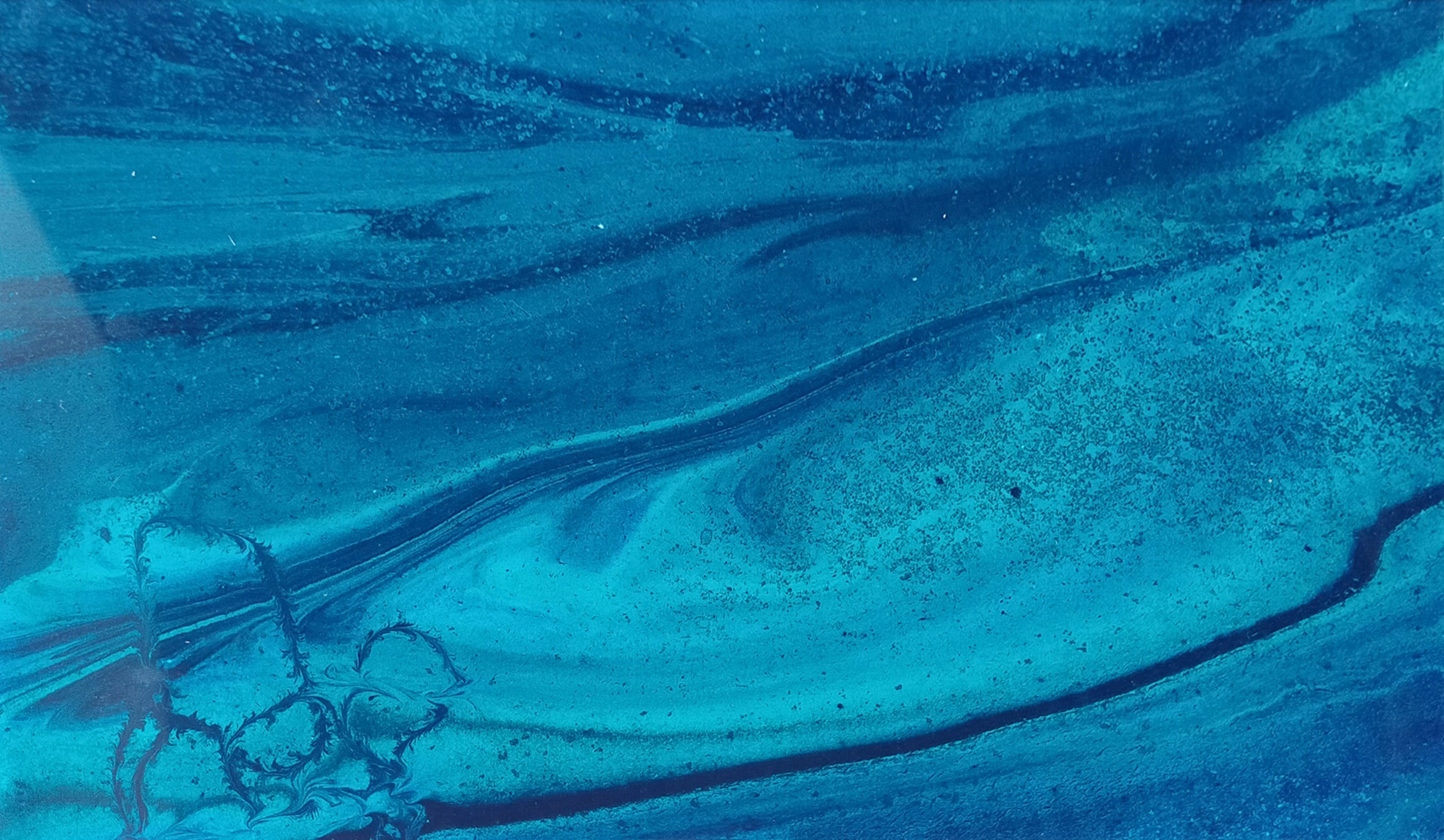

A post-consumer recycled polymer chip made from 100% marine plastic litter. From Material ConneXion database.

A post-consumer recycled polymer chip made from 100% marine plastic litter. From Material ConneXion database.

RECYCLING

Recycling is a process in which a material is brought back to an initial state, through mechanical or chemical transformation processes, in which it is possible to reprocess it again. In thermoplastics, typically we start from post-consumer waste or post-industrial waste to obtain secondary raw material in the form of re-printable granules, usually defined with an “R” in front of the polymer abbreviation (e.g. R-PET for PET recycled).

Recycled thermoplastic polyurethane (TPU-R) resin sourced from ski boots and extruded into 3D printing filaments. From Material ConneXion database.

Recycled thermoplastic polyurethane (TPU-R) resin sourced from ski boots and extruded into 3D printing filaments. From Material ConneXion database.

RECYCLED

If a product claims to be “recycled”, it means that it is manufactured from secondary raw materials. Recycled content can be post-consumer, or PCR, meaning that it comes from municipal waste, or pre-consumer (or post-industrial, i.e. coming from industrial waste). It is also important that the definition of “recycled” is accompanied by the quantity as a percentage of the overall content; and that the recycled content is guaranteed by a third-party certification, which traces the recycled materials along the value chain and makes the actual use of recycled plastics within the product transparent.

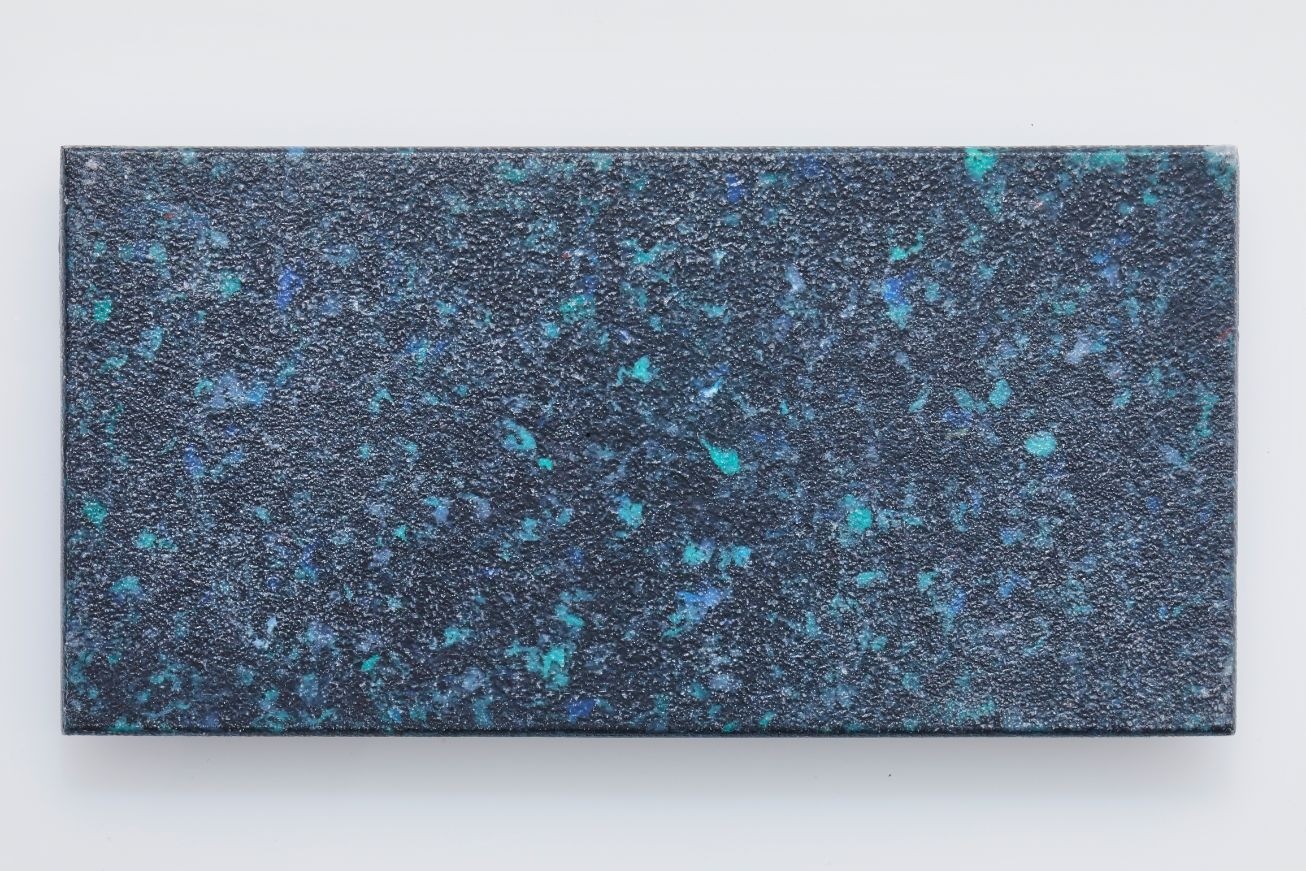

A material consisting of 100% heterogeneous waste plastic which would otherwise go to the incinerator. From Material ConneXion database.

A material consisting of 100% heterogeneous waste plastic which would otherwise go to the incinerator. From Material ConneXion database.

RECYCLABLE

A material or product with recycled content is not necessarily recyclable and vice-versa. All thermoplastics (of which plastic packaging and most everyday plastic items are made) are technically recyclable, with relatively little loss of quality; and yet that doesn’t mean they’re really recycled. According to OurWorldInData, in fact, the percentage of plastics that are recycled globally is still at 9% (this is an average value: Europe is doing a little better, but not much). To complicate the recyclability of plastics, there is often their complex formulation, with additives, pigments, combination of multiple materials (for example, in many plastic films for food packaging), as well as product design, which can make it difficult to separate the various pieces being recycled.

For a material to be recycled it is necessary not only that it is technically recyclable, but also that there is a downstream collection, separation and treatment chain; and finally, that there is a market capable of absorbing these secondary raw materials.

When a material is defined as “recyclable”, therefore, in the absence of other parameters or certifications, it refers only to the first point.

If you are interested in learning more about these and other topics related to the recycling of plastics, stay updated on the next editions of our courses and on the face-to-face events.

Cover: A unique purification process designed to remove color, odor, and other impurities from No. 5 plastic waste that results in an ultra-pure recycled (UPR) resin comparable to equivalent virgin polypropylene. From Material ConneXion database.