Textile production: alternative solutions for a sustainable future

The textile industry is one of the most polluting sectors in the world. Textile manufacturing plants emit 10% of global greenhouse gas emissions and, by producing a large amount of wastewater, cause 20% of industrial water pollution. Several studies show that water consumption and CO2 emissions in the textile sector are destined to increase drastically: it is estimated that from 2015 to 2030 water consumption and CO2 emissions will increase by at least 50%.

Images curtesy pixabay.com

Images curtesy pixabay.com

The quantity and composition of wastewater mainly depend on the raw material used and the textile production process. Over 100 million tonnes of textile fibers were produced in 2019, a demand that is set to double by 2030 due to population growth.

To reduce its environmental impact, the textile sector is investing in projects aimed at innovating the production process and at reconsidering the raw materials used.

Cellulose is, for example, the main component of wood and is the most abundant polymer (1) in the world: wood-based fibers could therefore play an important role within this challenge.

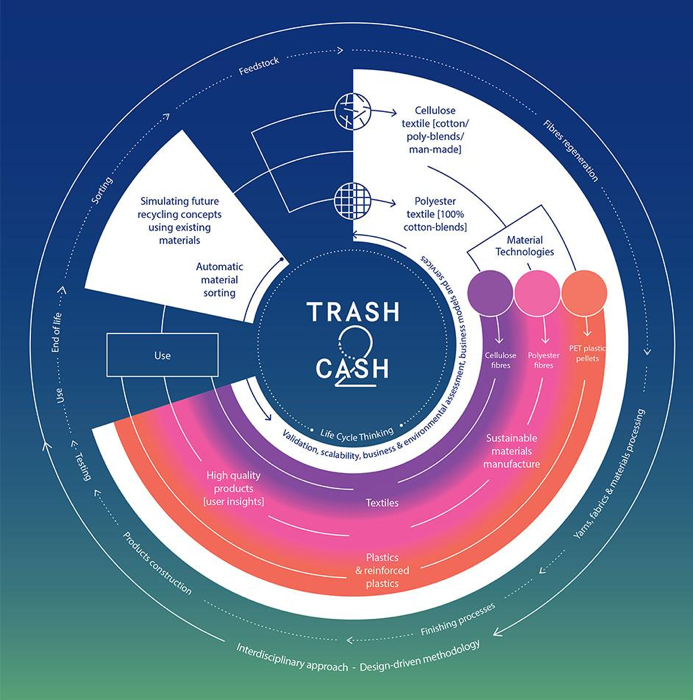

Materially has been dealing with this issue for several years: from 2015 to 2018 we took part in the European Trash-2-Cash project, which had the ambitious goal of implementing three particular production technologies capable of transforming textile waste into good quality secondary raw materials (2) to get new high value products.

—

1 Cellulose is a glucose polymer found in most plants

2 Secondary raw materials are made up of scraps from processing raw materials or materials derived from the recovery and recycling of waste.

Progetto Trash – 2- Cash

Progetto Trash – 2- Cash

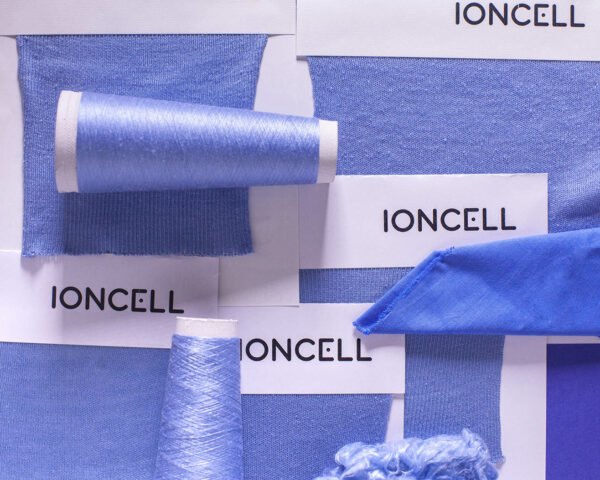

One of the three production technologies implemented by the project concerns the use of cellulose: Ioncell® is a technology that transforms used fabrics, cellulose pulp or even old newspapers into new textile fibers in a sustainable way and without the use of harmful chemicals. The process converts cellulose into fibers which in turn can be transformed into strong, long-lasting fabrics.

Image curtesy of Ioncell®, Photo by Eeva Suorlahti

Image curtesy of Ioncell®, Photo by Eeva Suorlahti

Still with the aim of trying to reduce the environmental impact of the textile sector starting from a new use of cellulose, Materially is currently a partner of the European project GRETE (Green chemicals and TEchnologies for the wood-to-textile value chain). In fact, the project aims to reduce toxic chemicals and modify industrial processes with a high environmental impact in the processing of cellulose fibers.

The technological innovations introduced by the GRETE project respond to the growing demand for sustainable textile fibers, which allow the use of Kraft pulp as a raw material for the production of high quality artificial textile fibers.

An important milestone will be the reduction of toxic chemicals through safe and sustainable technological solutions also for the production of artificial cellulose fibers. The GRETE project will also intervene on the phases of finishing and dyeing treatments of the fabrics, reducing pollution and water waste.

Follow the GRETE project: LinkediN, Twitter, Facebook, Instagram